INTRODUCTION

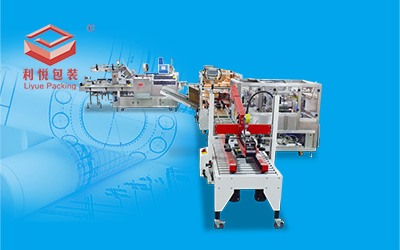

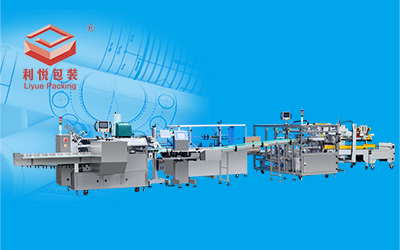

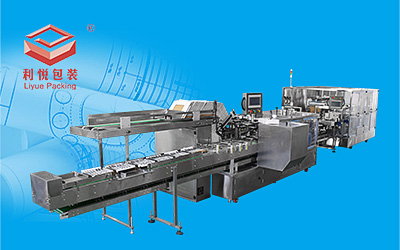

LY200-2 BAG-IN-BOX CARTONING MACHINE

MAIN TECHNICAL PARAMETERS

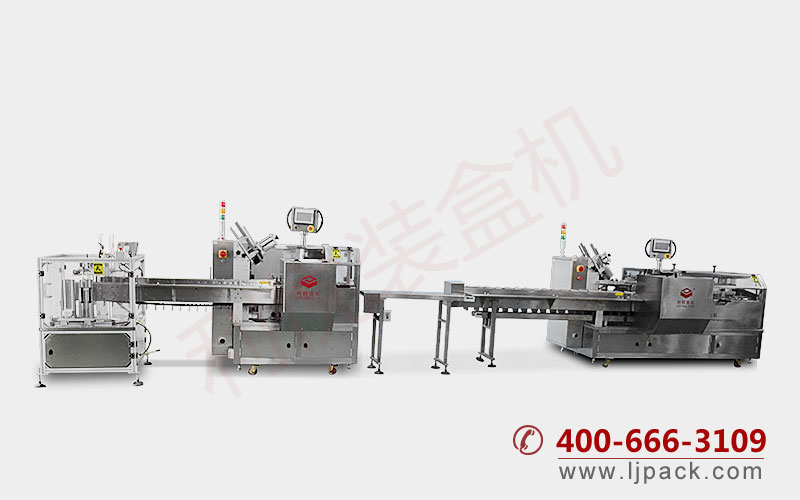

- Model: LY200-2 Insert Box type;

- Production speed: 15-35 box/min;

- Suitable for box size: L.130-200 W.50-160 H.20-50 mm;

- Paper requirements: 250-400g;

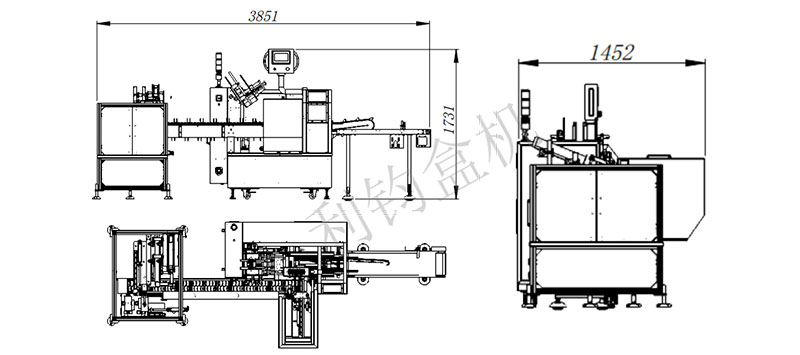

- Equipment dimensions: L.6880 W.1971 H.1732 mm;

- Machine weight: ≈2350 KG;

- Power supply: AC220V 50HZ-60HZ;

- Total power: 0.75KW;

- Air consumption: 15-80L/min(0.5-0.7Mpa);

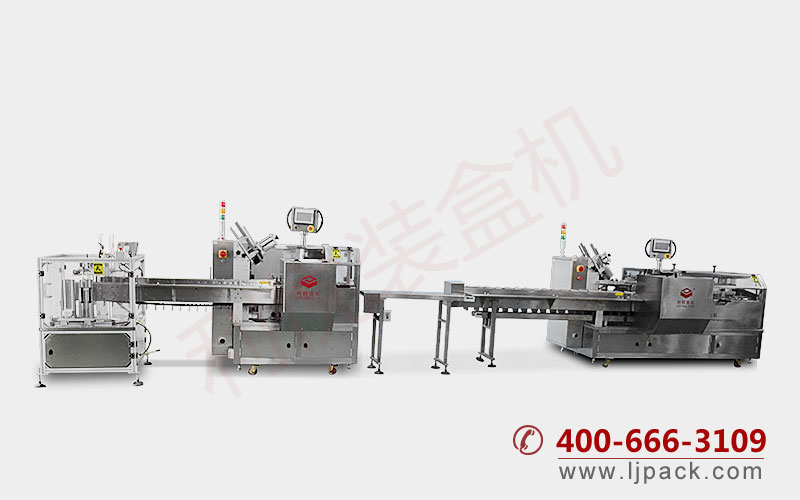

- Model: LY200-2 Sticky Box type;

- Production speed: 15-35 box/min;

- Suitable for box size: L.130-200 W.50-160 H.20-50 mm;

- Paper requirements: 250-400g;

- Equipment dimensions: L.6880 W.1971 H.1732 mm;

- Machine weight: ≈2380 KG;

- Power supply: AC220V 50HZ-60HZ;

- Total power: 4.5KW;

- Air consumption: 15-80L/min(0.5-0.7Mpa);

Equipment dimensions

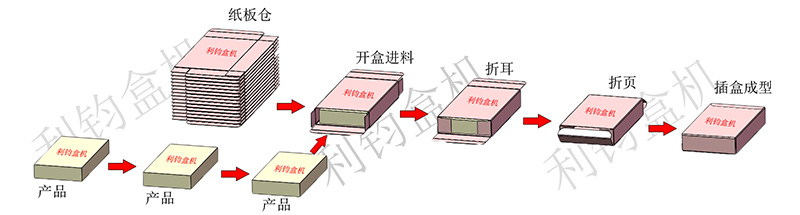

Packaging process

APPLICABLE FIELDS

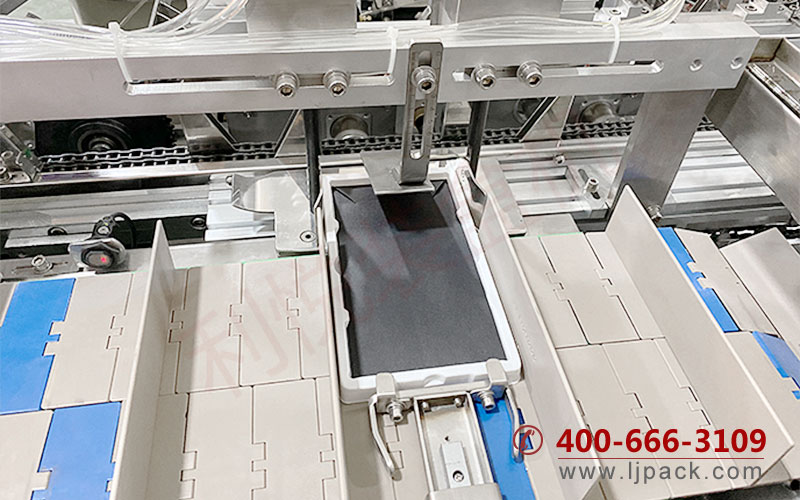

It is mainly used for automatic bagging and cartoning of mobile toughened film.

FEATURES

The equipment is an automatic cartoning production line specially developed by our company for mobile toughened film. Integrating automatic film feeding, leaflet, alcohol swab and applicator feeding, bagging, box opening, boxing, box folding and sealing, it has such features as compact and reasonable design, simple operation and convenient maintenance and servicing.

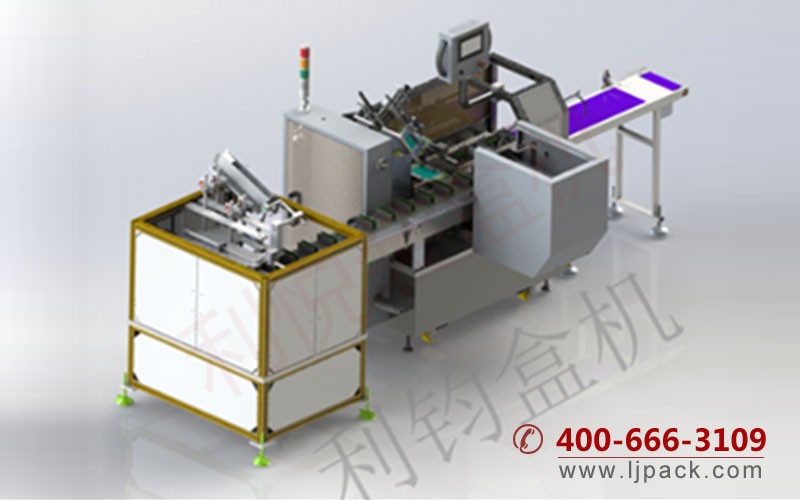

Within the specified range of the same equipment, the dial scale can be quickly adjusted to achieve the use of multiple specifications.

The parts that contact the product are made of SUS304 stainless steel.

High degree of automation: PLC programmable control system, man-machine interface displaying cartoning speed, quantity, automatic alarm for lack of cartons, no box opening in case of no product, fault reasons and other parameters.

The driving and friction parts strictly follow the standard, with less wear and less replacement of parts at later periods.

It can be equipped with the hot melt glue machine according to customer requirements. Box sealing can be achieved by hot melt glue spraying or mechanical glue spreading.

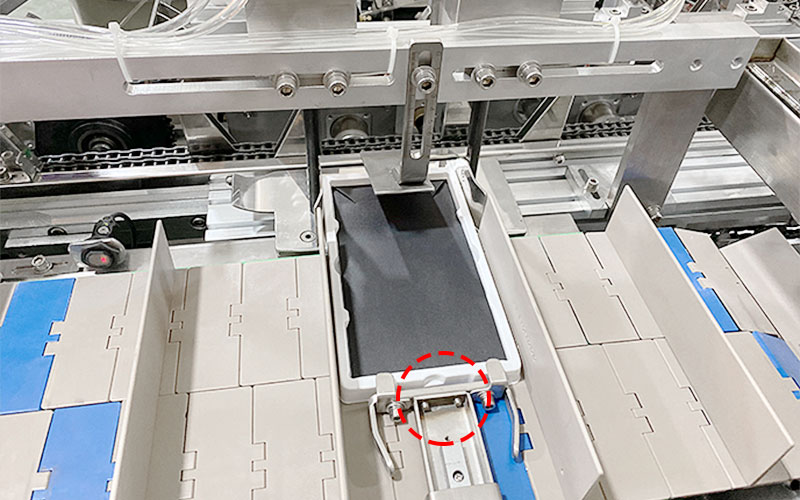

Part of the machine