INTRODUCTION

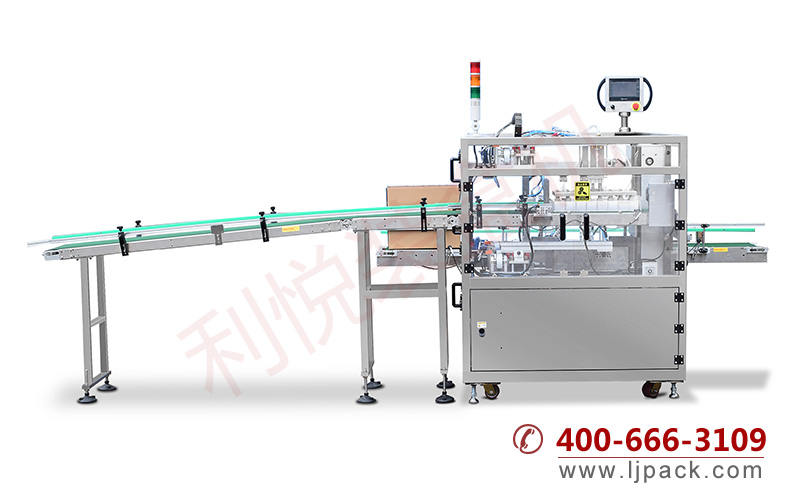

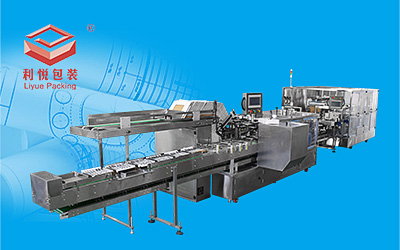

LY550WQ CARTONING AND CASE PACKING PRODUCTION LINE

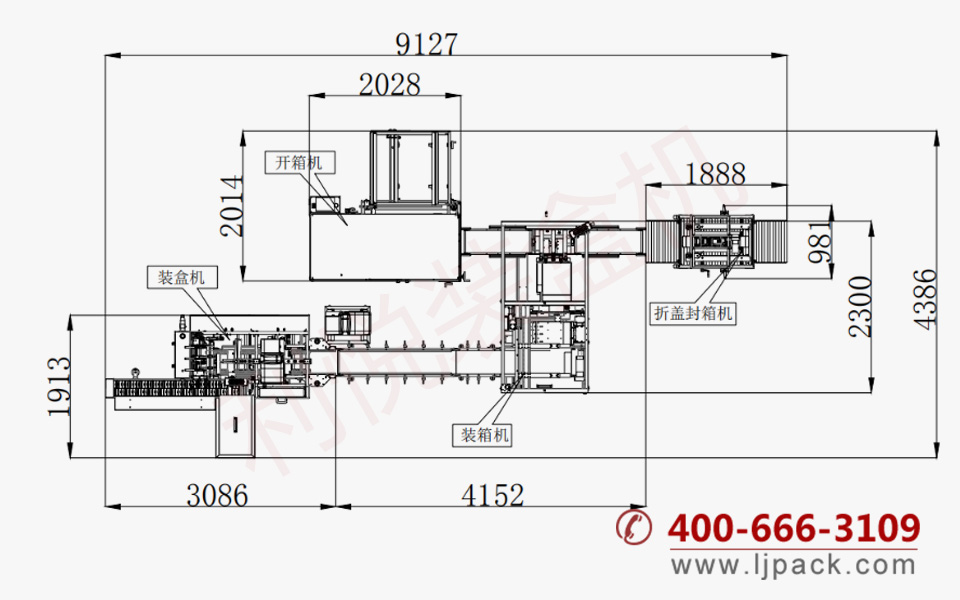

Equipment dimensions

MAIN TECHNICAL PARAMETERS

- Model: Box parking machine;

- Production speed: 5-40 box/min;

- Suitable for box size: L.130-250 W.60-160 H.50-110 mm;

- Paper requirements: 250-400g cardboard;

- Equipment dimensions: L.2685 W.1560 H.1672 mm;

- Machine weight: ≈1320 KG;

- Power supply: AC220V 50HZ-60HZ;

- Total power: 1.5KW;

- Air consumption: 15-80L/min(0.5-0.7Mpa);

- Model: Carton parking machine;

- Production speed: 1-8 Carton/min;

- Suitable for box size: L.300-600 W.200-500 H.200-500 mm;

- Paper requirements: Corrugated paper;

- Equipment dimensions: L.2300 W.1420 H.1505 mm;

- Machine weight: ≈860 KG;

- Power supply: AC220V 50HZ-60HZ;

- Total power: 2.5KW;

- Air consumption: 30-180L/min(0.5-0.7Mpa);

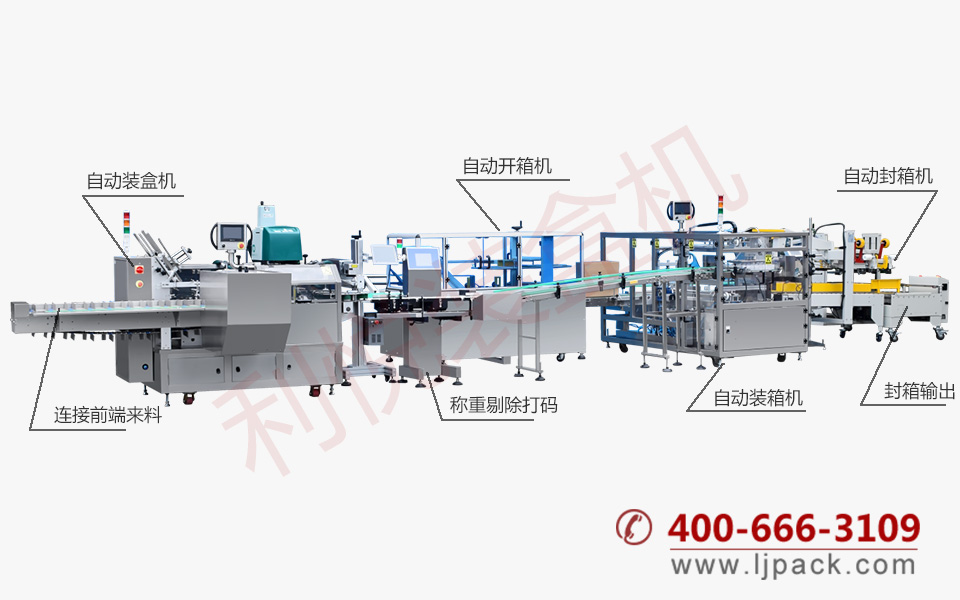

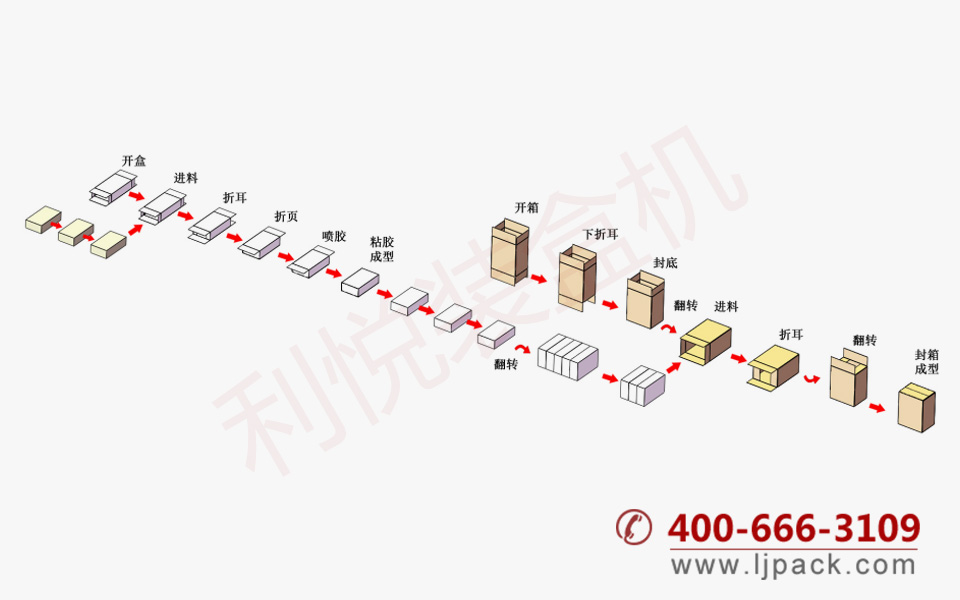

Packaging process

APPLICABLE FIELDS

The production line is mainly suitable for cartoning and case

packing of products such as food, medical supplies, toys, stationery, auto parts, cosmetics, hardware, daily commodities, etc.

FEATURES

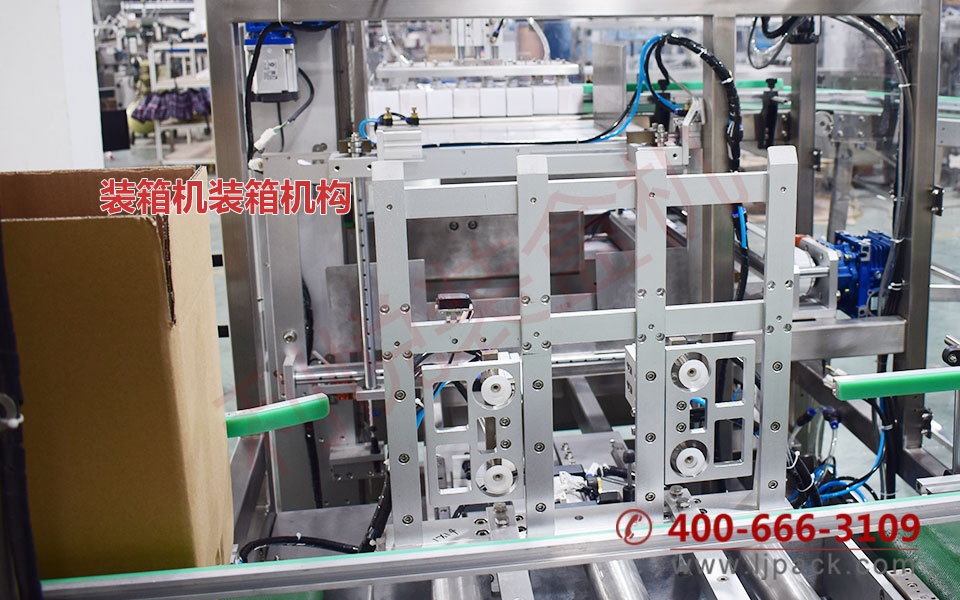

The unmanned automatic packaging production line integrates product cartoning, carton opening and bottom sealing machine, side pushing case packing, cover folding and case sealing.

The parts that contact the product are made of SUS304 stainless steel.

The driving and friction parts strictly follow the standard, with less wear and less replacement of parts at later periods.

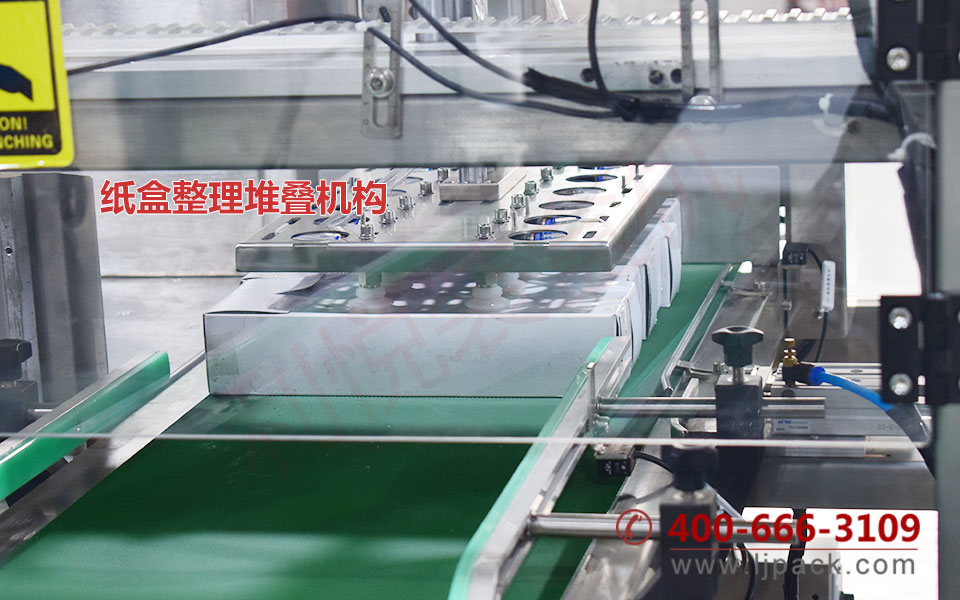

The packaging production line equipment has such advantages as manpower saving, neat, consistent and stable packaging appearance. The cartoning machine completes box opening, boxing, flap folding, page folding, glue spraying, glue sticking, code printing, labeling, and then case unpacking, bottom sealing, palletizing and case packing are carried out, and finally the cartons enter the cover folding “I”-shaped case sealing machine.

The equipment can be used singly or connected with various kinds of machinery and equipment such as the material sorting machine, manipulator, three-dimensional packaging machine, pillow packaging machine, vertical bag packaging machine, assembly machine, automatic filling machine, labeling machine and code printing machine at its front and rear ends for linked production.

part of machine