INTRODUCTION

MAIN TECHNICAL PARAMETERS

- Model: LY200-2-560 Insert Box type;

- Production speed: 20-80 box/min;

- Suitable for box size: L.90-200 W.40-160 H.15-50-70 mm;

- Paper requirements: 250-400g;

- Equipment dimensions: L.2976 W.1484 H.1651 mm;

- Machine weight: ≈900 KG;

- Power supply: AC220V 50HZ-60HZ;

- Total power: 0.75KW;

- Air consumption: 15-80L/min(0.5-0.7Mpa);

- Model: LY200-2-560 Sticky Box type;

- Production speed: 20-80 box/min;

- Suitable for box size: L.90-200 W.40-160 H.15-50-70 mm;

- Paper requirements: 250-400g;

- Equipment dimensions: L.2976 W.1484 H.1651 mm;

- Machine weight: ≈930 KG;

- Power supply: AC220V 50HZ-60HZ;

- Total power: 5.5KW;

- Air consumption: 15-80L/min(0.5-0.7Mpa);

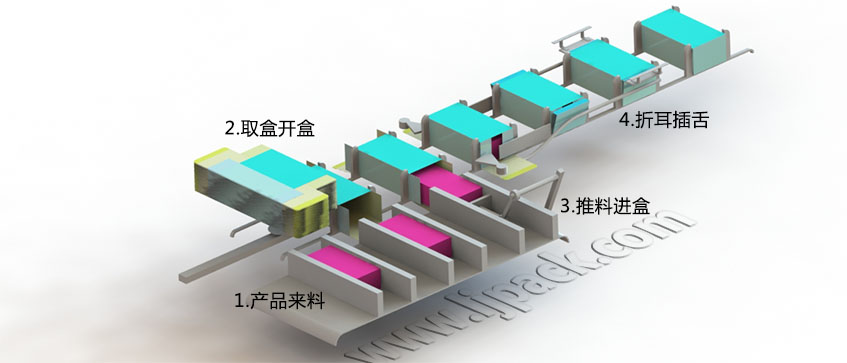

Packaging process

FEATURES

The equipment is one of the machines for mass production independently researched and developed by our company. Integrating box opening, boxing, box folding and sealing, it has such features as compact and reasonable design, simple operation and convenient maintenance and servicing.

The functions such as automatic material feeding, automatic tray feeding and leaflet feeding, character code and sequence number printing, waste rejection, etc. can be added at the front and rear ends of the equipment.

Within the specified range of the same equipment, the dial scale can be quickly adjusted to achieve the use of multiple specifications.

The parts that contact the product are made of SUS304 stainless steel.

High degree of automation: PLC programmable control system, man-machine interface displaying cartoning speed, quantity, automatic alarm for lack of cartons, no box opening in case of no product, fault reasons and other parameters.

The driving and friction parts strictly follow the standard, with less wear and less replacement of parts at later periods.

It can be equipped with the hot melt glue machine according to customer requirements. Box sealing can be achieved by hot melt glue spraying or mechanical glue spreading.

The equipment can be used singly or connected with various kinds of machinery and equipment such as the material sorting machine, manipulator, three-dimensional packaging machine, pillow packaging machine, vertical bag packaging machine, assembly machine, automatic filling machine, labeling machine and code printing machine at its front and rear ends for linked production.